Pneumatic Diverter Valve: A Complete Guide

03-10-25

Pneumatic diverter valves are essential components in various industrial applications, allowing for efficient control over material flow in pneumatic conveying systems. Whether in food processing, chemical manufacturing, or bulk material handling, these valves ensure smooth and uninterrupted operations by redirecting materials through different flow paths. Understanding how pneumatic diverter valves work, their benefits, and how to choose the right one for your application can make a significant difference in efficiency and productivity. In this guide, we will cover everything you need to know about pneumatic diverter valves.

What is a Pneumatic Diverter Valve?

A pneumatic diverter valve is a type of industrial valve that directs airflow or bulk materials within pneumatic conveying systems. These valves help route materials to different destinations, allowing for flexibility in processing and material handling. They are commonly used in industries such as pharmaceuticals, food and beverage, plastics, and chemical processing.

Pneumatic diverter valves operate using compressed air or gas to activate the valve mechanism, allowing for quick and efficient redirection of materials without manual intervention. This automation enhances process efficiency, minimizes downtime, and reduces the risk of contamination in sensitive applications.

How Does a Pneumatic Diverter Valve Work?

Pneumatic diverter valves function by controlling the direction of bulk materials or airflow in a system. Here’s a breakdown of their operation:

- Air Supply Activation – Compressed air or gas powers the actuator, which moves the valve’s internal components.

- Material Flow Redirection – The valve’s mechanism shifts, opening one passage while closing another to direct materials along the desired path.

- Sealing and Containment – High-quality seals ensure that materials do not leak, preventing contamination and maintaining process integrity.

- Automated or Manual Control – Depending on the system’s needs, the valve can be automated using sensors and controllers or operated manually.

Types of Pneumatic Diverter Valves

Choosing the right pneumatic diverter valve depends on factors such as material type, pressure requirements, and application environment. The most common types include:

1. Flap-Type Diverter Valves

These valves use a hinged flap to redirect materials from one pipeline to another. They are ideal for handling bulk solids and powders in industries like food processing and chemical manufacturing.

2. Plug-Type Diverter Valves

A rotating plug mechanism allows for seamless redirection of materials. These are often used in applications requiring high precision and minimal material degradation.

3. Swing Diverter Valves

Swing diverter valves use a pivoting gate to control material flow, making them suitable for heavy-duty applications that involve abrasive or dense materials.

4. Weigh Diverter Valves

These specialized valves ensure accurate weighing and distribution of materials, commonly used in batching and mixing applications.

Benefits of Pneumatic Diverter Valves

Investing in high-quality pneumatic diverter valves can provide numerous advantages:

- Improved Efficiency: Automated flow redirection speeds up material handling and reduces downtime.

- Reduced Contamination: Airtight seals prevent material cross-contamination in sensitive industries like food and pharmaceuticals.

- Versatile Applications: Suitable for a wide range of materials, including powders, granules, and bulk solids.

- Durability: Designed to withstand high pressures, temperatures, and abrasive materials.

- Energy Savings: Efficient air-powered operation minimizes energy consumption compared to mechanical alternatives.

Applications of Pneumatic Diverter Valves

Pneumatic diverter valves are widely used across various industries. Here are some key applications:

1. Food and Beverage Industry

- Redirecting grains, flour, sugar, and other bulk ingredients in processing lines.

- Ensuring contamination-free transfer of food-grade materials.

2. Chemical and Pharmaceutical Manufacturing

- Handling sensitive chemical powders and granules.

- Maintaining purity and preventing cross-contamination in pharmaceutical production.

3. Plastics and Resin Processing

- Directing plastic pellets and resins into molding machines or storage silos.

- Managing different types of polymers efficiently.

4. Mining and Cement Industry

- Transporting abrasive materials like cement, sand, and minerals.

- Ensuring reliable and durable operation in harsh environments.

Factors to Consider When Choosing a Pneumatic Diverter Valve

Selecting the right valve requires careful evaluation of several factors:

- Material Compatibility: Ensure the valve is made of materials resistant to the substances being handled. Stainless steel or coated surfaces may be required for corrosive materials.

- Pressure and Temperature Ratings: Verify that the valve can withstand the operating conditions of your system.

- Flow Rate Requirements: Choose a valve with the right capacity to handle your material volume.

- Automation Needs: Decide whether a manual or automated control system best suits your operations.

- Ease of Maintenance: Look for valves with simple cleaning and maintenance procedures to minimize downtime.

Installation and Maintenance Tips for Pneumatic Diverter Valves

To maximize the performance and lifespan of your valve, follow these best practices:

Installation Tips:

- Ensure proper alignment with the conveying system to avoid material blockages.

- Use high-quality seals and gaskets to prevent leaks.

- Test the valve before full-scale operation to confirm proper functionality.

Maintenance Guidelines:

- Regularly inspect seals and actuators for wear and tear.

- Clean the valve periodically to prevent material buildup and contamination.

- Lubricate moving parts as recommended by the manufacturer.

- Replace damaged components promptly to prevent system failures.

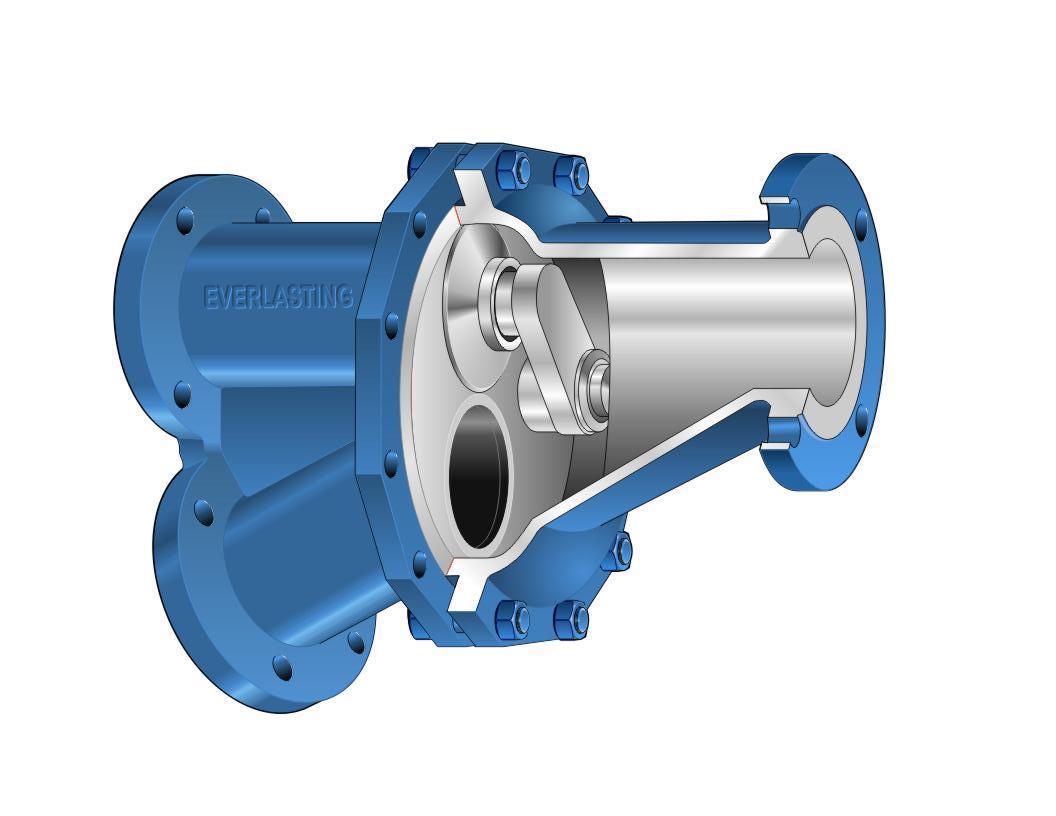

Why Choose Everlasting Valve for Your Pneumatic Diverter Valve Needs?

Everlasting Valve has been a trusted name in the valve industry for decades, providing durable and innovative solutions for demanding industrial applications. Our pneumatic diverter valves are engineered for longevity, efficiency, and high performance in various industries. With a commitment to quality and customer satisfaction, we ensure that every valve meets rigorous standards and delivers outstanding reliability.

Conclusion

Pneumatic diverter valves play a crucial role in optimizing material flow in industrial systems. Their ability to efficiently control direction, reduce contamination, and enhance automation makes them indispensable across numerous industries. Whether in food processing, pharmaceuticals, or heavy industries, selecting the right valve can significantly improve operational efficiency.

Ready to tackle your next valve project? Remember, Everlasting Valve stands prepared to help. Explore our website to explore our full range of compression valves, or contact our expert team for personalized guidance on choosing the correct valve for your specific needs.