Long Lasting Metal Seated Valves

07-23-19

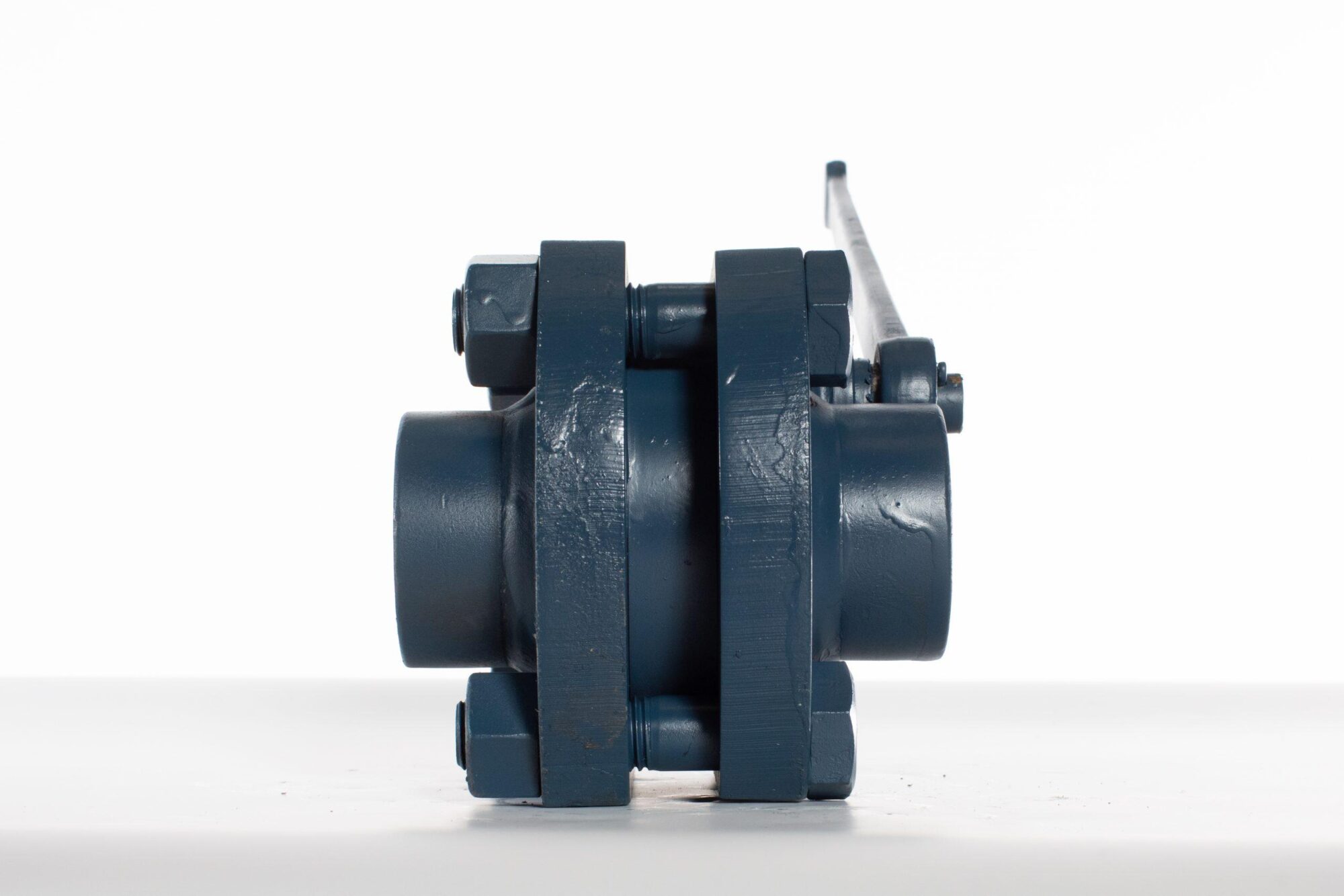

Metal Seated Valves

Metal seated valves (not metal seated ball valves) are perfect for high-temperature situations, longer-lasting than metal seated ball valves. Designed to stand up to difficult conditions, these valves will see you through extreme temperatures, high pressure and abrasive media. Different from how typical ball valves function, metal seated valves have taken engineering to a superior level and they stand up in in a variety of industry applications such as:

- Refining / Petrochemical

- Chemical Process

- Oil & Gas

- Mining

- Pulp & Paper

- Power Generation

When you are looking for the toughest valves for today’s most extreme applications, think long-lasting metal seated valves. Metal seated valve features include:

- perfect for high-temperature situations.

- longer-lasting than metal seated ball valves.

- a full port design as standard, which means you get high-flow capacity and minimum turbulences.

- perfect lapping process of ball and metal seats set which ensures absolute shutoff.

- for extreme applications, there is a rigid one-piece stem extension.

- various coatings and surface treatments are available, which means a reduction in corrosion and abrasion resistance.

- Inconel 718 Belleville spring means there is constant preload of ball/seats.

There are metal seated valves that can withstand heat up to 800 º F / 425º C. For temperatures that go beyond 800º F, there are metal seated valves for applications up to 1200º F / 650º C. These values have been meticulously engineered in all design aspects so that you can rely on them in the toughest conditions.

All valve parts of metal-seated valves have been put through a detailed metallurgical selection. Special surface treatments and hard coatings, as well as a comprehensive mechanical strength calculation and thermal expansion analysis, make this valve your best choice for applications involving the toughest materials.

To overcome today’s high-heat applications, present in a diverse range of critical services, selecting the appropriate hard surface technique is key. The surfaces of metal-seated valves must resist not just wear and corrosion, but must achieve total sealability. In addition, there must be a match between the hardening of the surface to its base material. Only when this is achieved will you find thermal stability and resistance to corrosion.

Surface Treatments

Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal, thus creating a case-hardened surface. It increases the hardness and wear resistance significantly in austenitic 300 series stainless steel. There are two types of Nitriding processes:

- Low-Temperature Plasma Nitriding (LTPN) – this type of nitriding is seen at temperatures of 750º F and it produces a hardening effect on the stainless steel. LTPN results in a nitride layer with a micro-hardness as high as 62HRC. On an untreated surface, micro-hardness is typically no more than 25HRC. This means that the wear resistance on the stainless steel has been greatly improved, and corrosion and resistance properties have been preserved. The maximum allowable temperature for valves using the LTPN treatment is 350º C or 660º F.

- Salt-bath Nitriding (DHN) – this second treatment at a temperature of 550º C or 1020º F is similar to the LTPN effect. Corrosion resistance to the stainless steel is reduced with this treatment due to its extreme high temperature. It is limited to applications with a minimum PH level of 6. This application is ideally suited on thermal oil and hot air applications.

Coatings

In surface coating, an outer layer of new material is introduced to the surface layer. The following types of surface coatings are available:

- Cr3C2 (Chromium Carbide) – this coating resists temps up to 815º C. The valve maximum temperature is 650º C. This surface coating is used in a variety of multi-purpose applications including refining and hot catalyst handling services as well as power generation.

- WC-Co (Tungsten Carbide) – this coating is applied mainly to 400 series martensitic stainless steel and results in a micro-hardness as high as 72HRC. WC-Co is a wear resistance and dense coating which works as a chemical resistance to sulphur environments.

- Stellite – this type of coating is cobalt-based and provides an excellent mechanical wear resistance as well as good corrosion resistance at temperatures up to 538º C or 1000º F. Stellite is typically used in the pulp and paper industry as well as in refining applications.

Our company manufactures four unique valves, all of which meet the needs of a huge range of severe temperature applications. Our valves can replace ball valves, gate valves, globe valves, and pinch valves, all available in diverse functionalities.

Our metal seated valves are manufactured and made in the USA. We have representatives in various locations around the world who will work with you to directly place your order with us. For all of your valve order information, contact us today.