Gate Valves and Their Benefits

08-05-24

Gate valves are isolation valves that allow or prevent fluid flow in pipelines carrying steam, oil, water, air, and compressed gas. They operate through a threaded stem that turns multiple times to open and close the valve. A wedge is inserted in the flow path to allow or obstruct fluid movement in the pipeline network.

When gate valves are partially opened and used as control or regulating valves, high-velocity flow causes shearing and damages the seating surfaces. Also, the opening of a gate valve is not proportional to the fluid flow rate when it is partially opened.

Uses of Gate Valves

The primary use of gate valves is to achieve free bore and minimum pressure loss. The gate valves can also isolate specific areas in a pipeline network for repair, maintenance, new installation, or rerouted flow. Gate valves with a by-pass achieve the following:

- Delay filling of pipelines.

- Ensure continuous flow to avoid stagnation.

- Balanced pipeline differential pressure, lower torque requirement of the valve, and one-person operation.

Applications of Gate Valves

The applications of gate valves range from residential to industrial, such as HVAC, steam, compressed air, oil, water treatment and water distribution and boiler houses. Some of the reasons for the use of gate valves in specific areas are as follows:

- Water allow for water control when fully opened or fully closed. Their slow operation helps prevent the effects of water hammer.

- Slurries provide an unobstructed flow of slurry. Knife gate valves easily cut through the slurry when closing.

- Viscous media provide unobstructed flow for grease and oil. Cleaning of the pipeline network is made easy through pigging.

Types of Gate Valves

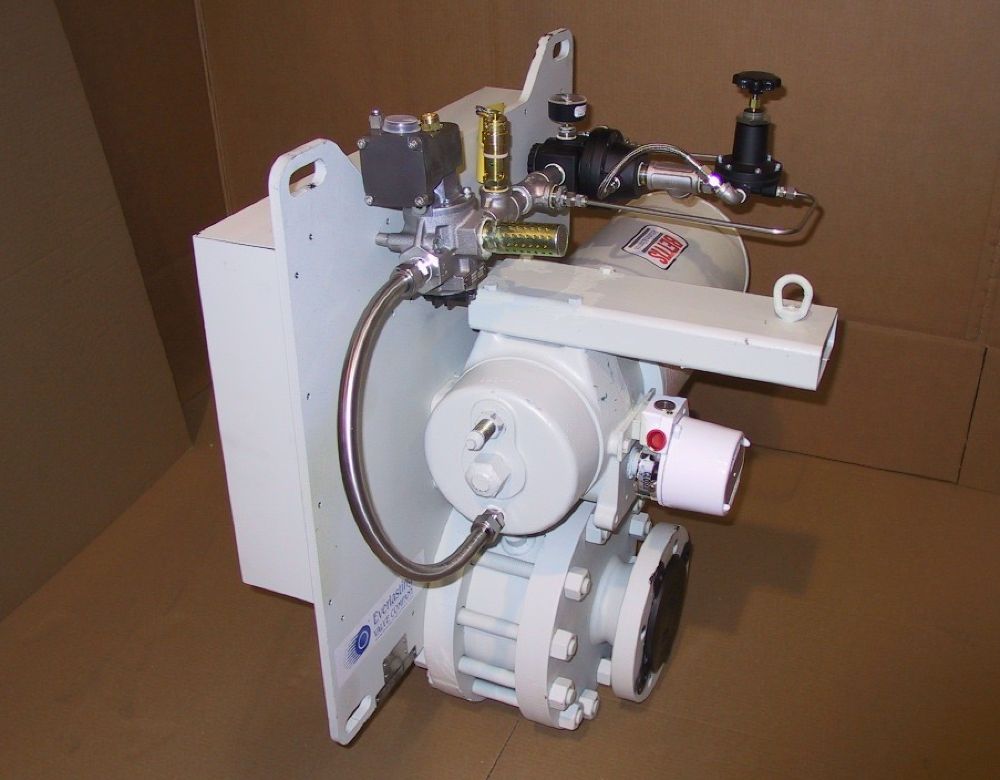

Gate valves come in different sizes, materials, and configurations, and various manufacturing technologies achieve the desired effective seal for multiple applications. Some categories for classifying types of gate valves are actuation method, stem, seating, and wedge.

1. Actuation Method

Manual gate valve opening and closing the valve is achieved by manually turning the handwheel. On-site operation is required.

Pneumatic gate valve compressed air spins the stem, lowering and raising the gate. Remote operation is possible.

Electric gate valve – An electric motor replaces the handwheel in the lowering and raising of the gate. Remote operation is possible.

2. Stem

Rising Stem valves are fixed to the gate. The stem rises and falls as the valve is opened and closed. These valves require more operation space and are not suitable for buried installations.

Non-rising stem valves are threaded to the gate. The stem does not rise and fall as the valve is opened and closed.

3. Seating

Metal seat – A wedge slides to a groove within the invert of the valve body. The groove often traps solids in the fluid, making them lose their ability to be drop-tight over time.

Resilient seat a wedge, usually made of ductile iron, encapsulated in elastomer material that provides a tight seal between the rim and valve body.

4. Wedge

Parallel gate valve uses a flat gate fitting between a pair of parallel seats. The knife gate valve is of this type and is typically self-cleaning with each passage of the seat rings during opening and closing.

Wedge gate valve uses two inclined seats and a slightly asymmetric inclined gate. They have higher durability due to less wear on the seats. Water distribution systems mostly use this valve.

Features of Gate Valves

Different gate valves have unique applications to ensure the effective operation of a pipeline network. The valve material is usually an iron or steel alloy. The internal and external parts are often epoxy-coated for corrosion protection. The main parts of a gate valve are:

- Valve body

- Wedge

- Stem

- Seating

- Bonnet

- Packing

- Actuator

The gate valves have a wide range of nominal diameter sizes and come in flanged by flanged or flanged by grooved configurations. They can also handle fluids of various degrees of pressure and temperature. Given the variety available, selecting a suitable gate valve depends on the intended application, employed specifications, and standards adhered to.

Benefits of Gate Valves

Gate valves have many advantages. Other than their numerous applications, some of the advantages of gate valves are:

- The wide application range makes gate valves suitable for use with most fluids, such as steam, oil, water, and gas, for industrial and residential purposes.

- Their compact structure requires little space to operate, and a ductile body makes them more durable. They also come in multiple configurations and sizes.

- Ensure minimum pressure loss and free bore – there is a straight media channel in the valve and low resistance to flow.

- Enable easy use of a pig during pipe cleaning.

- Opening and closing the gate valve requires less effort than the shut-off valve, as the movement of the gate is perpendicular to the flow direction of the fluid medium.

- The low torque requirement requires less effort to operate a gate valve.

- A tight seal when the gate valve is closed ensures equal pressure on either side of the valve.

- Provide unobstructed fluid flow.

- It reduces water hammer effects due to the long gate valve opening and closing periods.

- Enables bidirectional flow – the fluid can flow in either direction in the pipeline network, given that the two sides of the channel are symmetrical. Bi-directional flow also makes installation and change of flow route convenient.

Downside of Gate Valves

Despite their wide applications and various advantages, gate valves have drawbacks. Some of the disadvantages of gate valves are:

- The fluid flow rate is not proportional to the valve opening.

- Unsuitable for use as regulating and control valves.

- Experience wear when partially opened.

- Slower compared to quarter-turn valves.

- Worn-out parts are hard to repair.

Final thoughts

Gate valves are ideal for multiple applications but are not suitable for others. They are excellent at maintaining flow rates with minimal pressure drops and offer a tight seal for the fluid medium along their systems. However, they are unsuitable for fast flow control or regulation and require regular maintenance when used with high-velocity flow fluid when operated frequently.

Careful consideration of the type, specification, standard, and application is required when choosing the appropriate gate valve, as each valve operates uniquely in different conditions.

Interested in our services? Contact us here or call today to request a quote.